gestyy.com/w2uVwV gestyy.com/w2uK4G gestyy.com/w2uJPF viid.me/qxgvBT viid.me/qa5603 sh.st/boMkZ sh.st/c4otk sh.st/zjoYf sh.st/dPFrI sh.st/dY8c7 sh.st/s6aZD sh.st/s6a31 sh.st/d0Q2j sh.st/d0Q9W

The good side of robots: we can retire before

- Obtener enlace

- X

- Correo electrónico

- Otras aplicaciones

Enlarge picture

Enlarge picture

Robotics and artificial intelligence advance, and with them, the fear of a future in which machines dominate all sectors of human life, starting with the labor market. The most positive estimates, such as that made by the McKinsey Global Institute , mention 1.1 million technology-threatened jobs around the world. Others, such as the World Economic Forum, put more than five million jobs at risk of robotization in the 15 most industrialized countries in the world. There is, however, a good side in the so-called fourth industrial revolution: the payoff generated by increased productivity thanks to technology can be used to improve the quality of life and provide benefits to workers. That is the conclusion of the latest report presented by the Trades Union Congress (TUC), the British trade union center, which indicates that financial gains should translate, for example, into higher salaries and more retirement time.

MORE INFORMATION

MORE INFORMATION

Artificial intelligence will generate 10% of British GDP growth by 2030, according to consultancy PwC . "With these benefits, it should be a priority to allow more people to enjoy a decent retirement," says Kate Bell, TUC's director of economics. The British Government is currently considering the possibility of saving 0.3% of GDP by raising the retirement age to 68, which would affect the workers who are now 40 years old. "In an aging society, where people have to work longer, robotics can reverse that scenario. It would be a way of ensuring that new technologies allow a fairer share of the rewards of work and help those whose working lives have been affected by robots, "says the economist.

The report mentions that the risk of not promoting the equal distribution of automation profits is to return to the scene of the industrial revolution of 1950, when one in three workers was in the manufacturing industry and only one in 12 worked in professional services and technicians. By 2016, the numbers had been reversed, but jobs lost in manufacturing were not replaced by similar ones and, according to the publication, wages in the former industrial zones are still 10% below the labor average.

Bell believes that shared benefits also enable increased investment in workplace training and give workers the opportunity to negotiate directly with business owners to obtain a share of the economic gains from technology through wage increases . "That would give workers the right to rethink aspects of their careers when they are middle-aged," she says.

Training and adaptation

The report notes that, although previous waves of technological change have not led to a general loss of jobs, they have changed the labor market. The economic historian James Bradford, University of Berkeley, recalls that until 1970, rapid technological progress destroyed jobs requiring muscle strength, but created a demand for workers who know operate the new equipment. "And the higher productivity generated salary increases and people began to invest more in leisure, which consequently created more opportunities in that sector," he adds.

"In an aging society, where people have to work longer, robotics can reverse that scenario"

Frances O'Grady, secretary general of the TUC, shares that vision: "Some of the current jobs will not survive, but new jobs will be created and people should be able to occupy them if their work becomes obsolete," Frances O'Grady, Secretary General of the TUC. The trade union central defends the importance of investing in training not only young people, but also workers in factories to adapt to the changes introduced by robotics and artificial intelligence. The report indicates that this adaptation is easier when workers have a voice in defining the use of new production techniques.

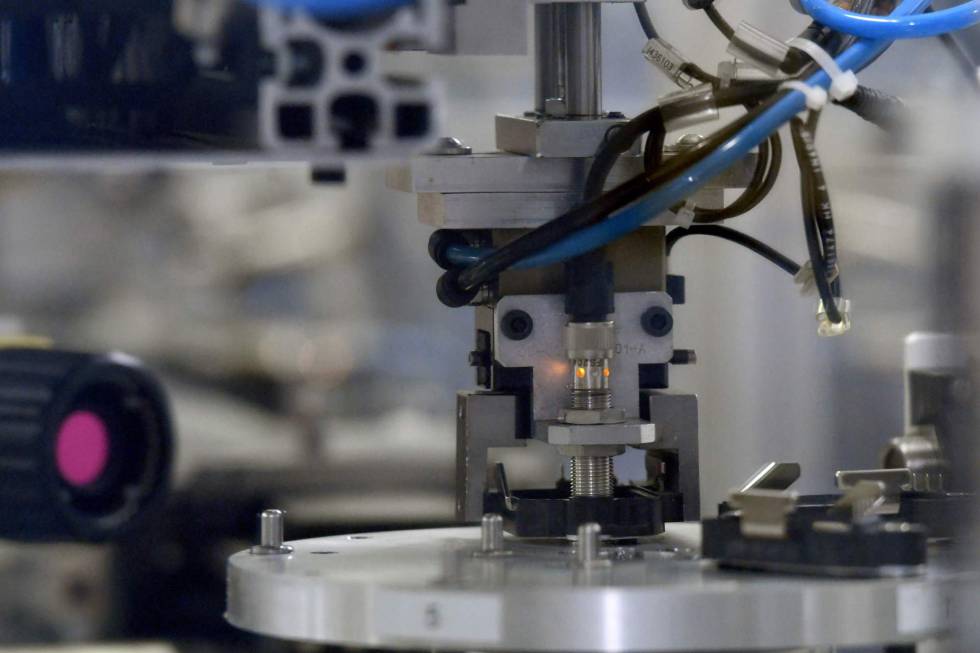

An example is the Airbus production center in Hamburg, where 12,500 people work and started to implement its 4.0 industry plan in 2015, ie computerized manufacturing with all processes interconnected by Internet of Things (IoT). To do this, members of the management of the company met with the workers' union, experts and German authorities to work together the implementation roadmap and the parties reached an agreement: all workers will receive training in robotics and artificial intelligence and there will be no reduction of jobs until 2020. The result was, in the words of Jan Hinz, vice president of the General Business Council of Airbus Germany, "the fusion of technology, employment and productivity."

www.elpais.com

- Obtener enlace

- X

- Correo electrónico

- Otras aplicaciones

Entradas populares de este blog

Descargar Photoshop CC FEBRERO 2017 MAC GRATIS

Descripción: Mayor libertad, velocidad y potencia para hacer realidad imágenes increíbles. Conseguirás decenas de funciones nuevas y renovadas, entre las que se incluye la herramienta de enfoque más avanzada del mercado. Comparte tu trabajo directamente desde Photoshop® CC en Behance® para recibir comentarios y mostrar tus propios proyectos. Accede a funciones nuevas en cuanto estén disponibles. Disfruta de todo tu mundo creativo en un único lugar. Contenido Adobe Photoshop CC 2014 Activado Plugins: Imagenomic y Nik Software Camera Raw 8.5 Photoshop cc 2017 Mejoras de los objetos inteligentes Conserva los vínculos a archivos externos empaquetándolos automáticamente en un solo directorio. También puedes convertir tus objetos inteligentes incrustados existentes en objetos inteligentes vinculados. Composiciones de capas mejoradas Ahorra tiempo: ahora puedes cambiar la visibilidad, la posición o la apariencia de una capa en una composición de capas y, a continuación, sincr...

ADOBE ILLUSTRATOR cc FEBRERO 2017 gratis MAC OS Full ENERO [ACTUALIZADO]

El programa Adobe Illustrator es uno de los más utilizados, sino el más extendido, para crear gráficos vectoriales de gran potencia. Nos permite también dibujar en perspectiva de hasta 3 puntos y nos hace disponer de unas herramientas fantásticas para dibujar y diseñar. Podemos crear formas de un nivel absolutamente profesional, con funciones muy realistas que podremos combinar. Entre ellas, las flechas de ancho variable o el degradado perfecto de colores. También dispondremos de la posibilidad de esos dibujos en perspectiva que darán una apariencia muy real a nuestras creaciones. Pinceles que simulan perfectamente los pinceles de cedra que utilizamos en la vida real, degradados y transparencia en los objetos... Para los fanáticos de la tipografía, este programa lo tiene todo, y es compatible con las fuentes OpenType. Sombras, texturas... mil opciones en los atributos de cada objeto o texto. ...

Comentarios

Publicar un comentario